Surface Treatment Services

Over 50 years of precision finishing expertise. We maintain NADCAP accreditation and work to aerospace, defence, and industrial specifications.

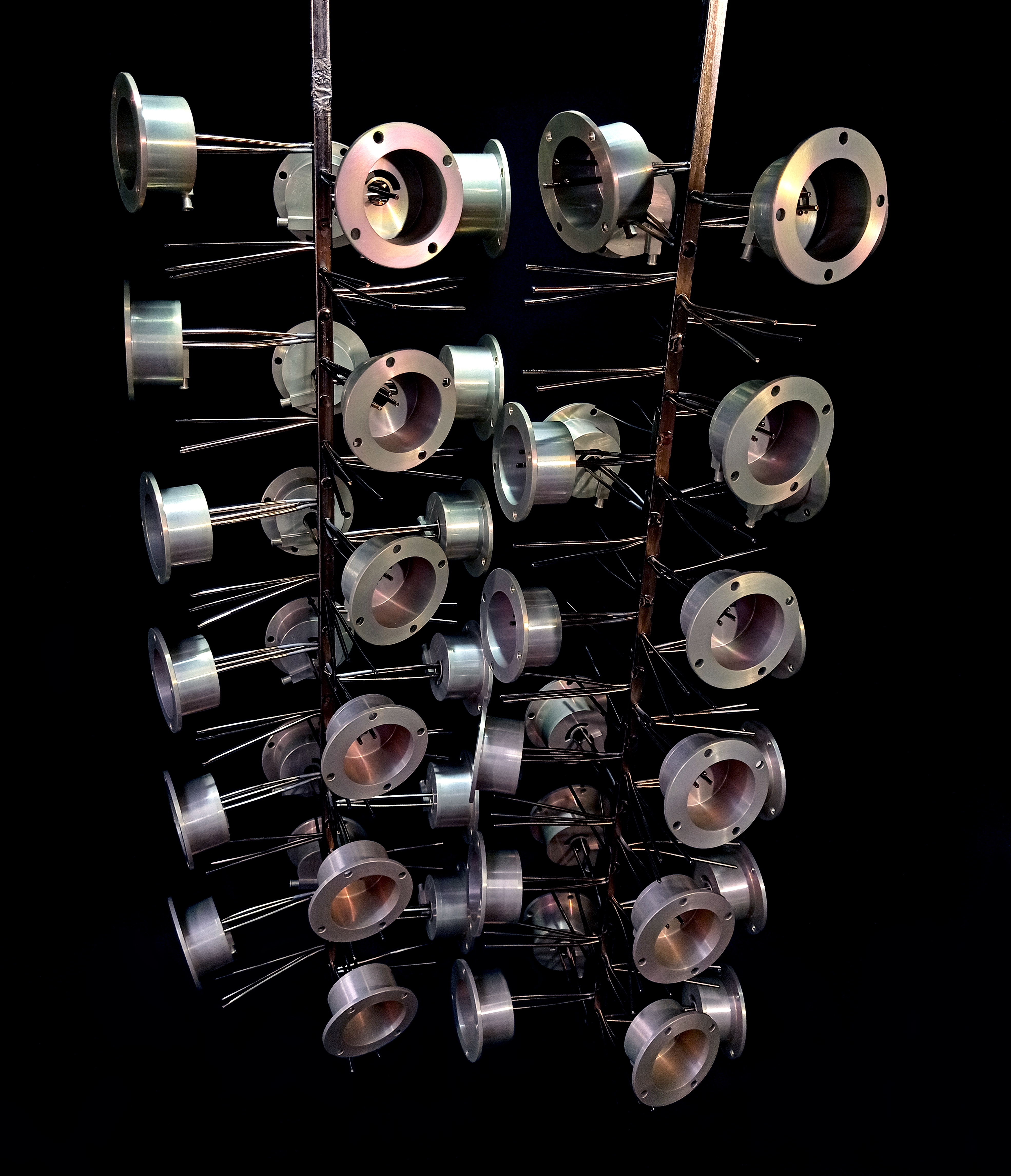

Type III Hard Anodising

Exceptionally hard, wear-resistant oxide coatings on aluminium alloys. The process creates a thick anodic layer (typically 25-100 microns) that significantly increases surface hardness to around 400-600 HV.

Our hard anodising tanks handle components up to 5.5 meters, with precise temperature control and current density management to ensure consistent coating thickness and properties.

Specifications & Standards

- DEF STAN 03-24/3

- MIL-A-8625 Type III

- AMS 2469

- NADCAP accredited process

Properties

- Coating thickness: 25-100+ microns

- Surface hardness: 400-600 HV

- Excellent wear and abrasion resistance

- Enhanced fatigue resistance

Type II Sulphuric Acid Anodising

Decorative and protective coatings from 5-25 microns. Standard sulphuric acid anodising provides excellent corrosion resistance and is ideal for both functional and decorative applications.

Chromic Acid Anodising

Thinner films (1-17 microns) with minimal dimensional change. Ideal for close-tolerance components and as a paint base for aerospace applications. Processes to DEF STAN 03-24/1, MIL-A-8625 Type I.

Dyeing & Finishing

Various colours available with sealed finishes for enhanced corrosion resistance and decorative purposes:

- Natural (clear/silver)

- Black

- Bronze, gold, blue, red (subject to batch size)

- Multiple sealing options available

All anodised finishes can be sealed using hot water, cold seal, or sodium dichromate methods for enhanced corrosion protection.

Thin chemical films (0.5-3 microns) providing corrosion protection and excellent paint adhesion for aluminium and its alloys.

Alochrom 1200

Hexavalent chromium process. Licensed and compliant for applications requiring traditional chromate conversion.

SurTec 650V

Trivalent chromium process offering excellent corrosion protection with reduced environmental impact.

Iridite NCP

Non-chromate process. RoHS compliant for applications requiring chromium-free solutions.

Iridite 15

Suitable for aerospace, castings, machined components, and magnesium alloys.

We maintain hexavalent chromium licenses where required and offer non-chromate alternatives for RoHS compliance.

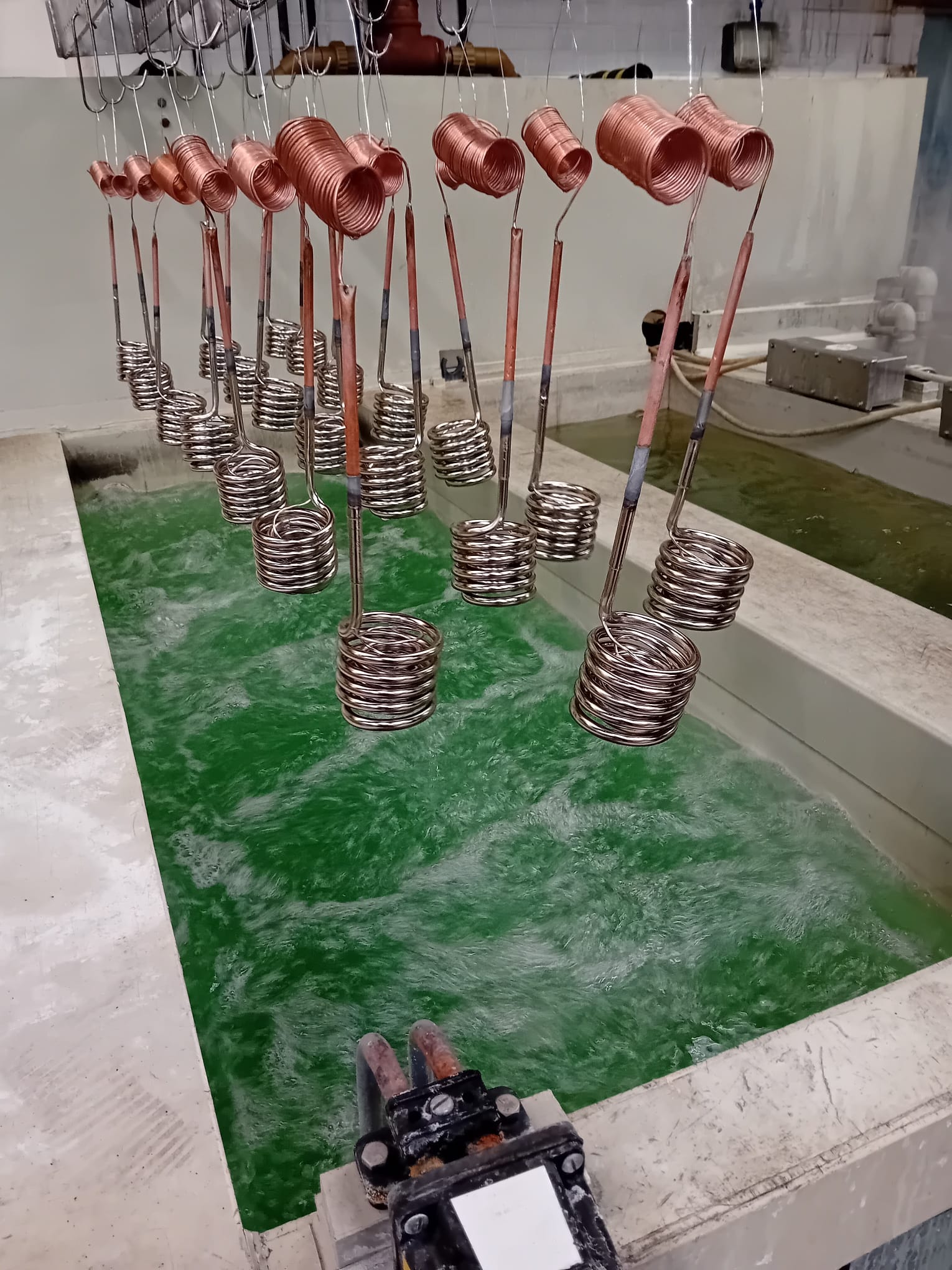

Uniform coating thickness regardless of component geometry. Excellent corrosion resistance, solderability, and controlled magnetic properties.

Phosphorus Variants

- High Phosphorus (10-13%) - Maximum corrosion resistance, non-magnetic

- Medium Phosphorus (5-9%) - Balanced properties, good wear resistance

- Low Phosphorus (1-4%) - Higher hardness, suitable for wear applications

PTFE Composite Plating

Co-deposited PTFE nickel for enhanced lubricity and reduced friction in moving components.

Coating thickness: 5-50+ microns depending on application requirements. Hardness up to 500 HV (higher after heat treatment).

Additional Processes

Surface Preparation

- Precision masking for localized treatments

- Degreasing and cleaning

- Surface activation

Stripping Services

- Anodising stripping (all types including hard anodising)

- ENP stripping

- Strip and re-coat services

- Component salvage and refurbishment

Passivation

- Stainless steel passivation

- Enhanced corrosion resistance

- Surface contamination removal

Post-Treatment Services

- Multiple sealing methods (sodium dichromate, hot water, cold seal)

- PTFE coating application (Anolube)

- Heat treatment services (pre and post-plating)

Specialized Services

Aerospace & Defence

- NADCAP accredited processing

- Callibrated dry film readings (On Certificate of conformity)

- Enhanced quality control and traceability

- Operator controlled variable (OCV) monitoring

- Full compliance with aerospace specifications

Custom Solutions

- Multi-stage treatment processes

- Part-specific processing procedures

- Custom thickness specifications and tolerances

- Specialized jigging/internal cathodes for deep holes

- Engineering support and process development

Materials We Process

Aluminium & Alloys

All aluminium alloys suitable for anodising and chemical conversion coatings. Experience with 2000, 5000, 6000, and 7000 series alloys.

Steel & Ferrous Metals

Carbon steel, stainless steel, and tool steels for electroless nickel plating and passivation services.

Non-Ferrous Metals

Copper, brass, titanium (anodising), and magnesium (chemical conversion). Specialized processing for each material type.