Summary. We excel in anodising large aluminium parts, providing robust protection, enhanced aesthetics, and architectural durability through hard anodising aluminium. As leading specialists, they ensure metal components gain corrosion resistance, electrical insulation, and customisable appearances, catering to various industrial needs with their expertise and seamless services.

Anodising is one of the most effective metal coating mechanisms available today. Whether you are hard anodising large aluminium parts or those of a smaller form, the anodising process is considered to be incomparable. This is especially in the case of hardening and strengthening complex metal parts. However, anodising can achieve several outcomes, whether that be for protection, decoration or for architectural purposes.

We’re going to take a closer look at anodising’s benefits and how they can optimise aluminium parts for several sectors. Here at Hard Anodising Surface Treatments Ltd, we have collated years of experience in this industry. As a result, this has led us to become leading anodising specialists in the West Midlands.

What can anodising achieve?

Depending on the business’s needs, anodising can enhance metal components for a number of reasons. See below for more information.

Protection

Anodising large aluminium parts for a robust protective layer is one of the most popular variations of this finishing process. This type of anodic coating produces a level of film that ensures metal surfaces stay durable and resistant to corrosion. In addition, it offers excellent electrical insulation. Consequently, it is commonly in use in the industrial sectors.

With a thickness of between three and thirty microns, it is less dense than that of hard anodising aluminium. Therefore, people commonly refer it as semi-hard anodising.

Decoration

Optimum aesthetics can also be achieved through anodising aluminium. This type covers a range of components that offers variable integrities. Although its natural colouring is of a silverish tone, dyestuffs can be used to suit a range of applications. This includes on-brand instrument panels and systems found in the public eye. Furthermore, textures can be customised through brightening and dulling, using powerful chemicals.

Architectural

Last but not least, anodising large aluminium parts can be for architectural purposes too. For instance, structures that need to withstand extreme weather conditions as anodic coatings offer mechanical performance and corrosion resistance. Additionally, external architecture requires a certain level of aesthetic appearance. This can be improved even further through integral colour anodising or dyeing.

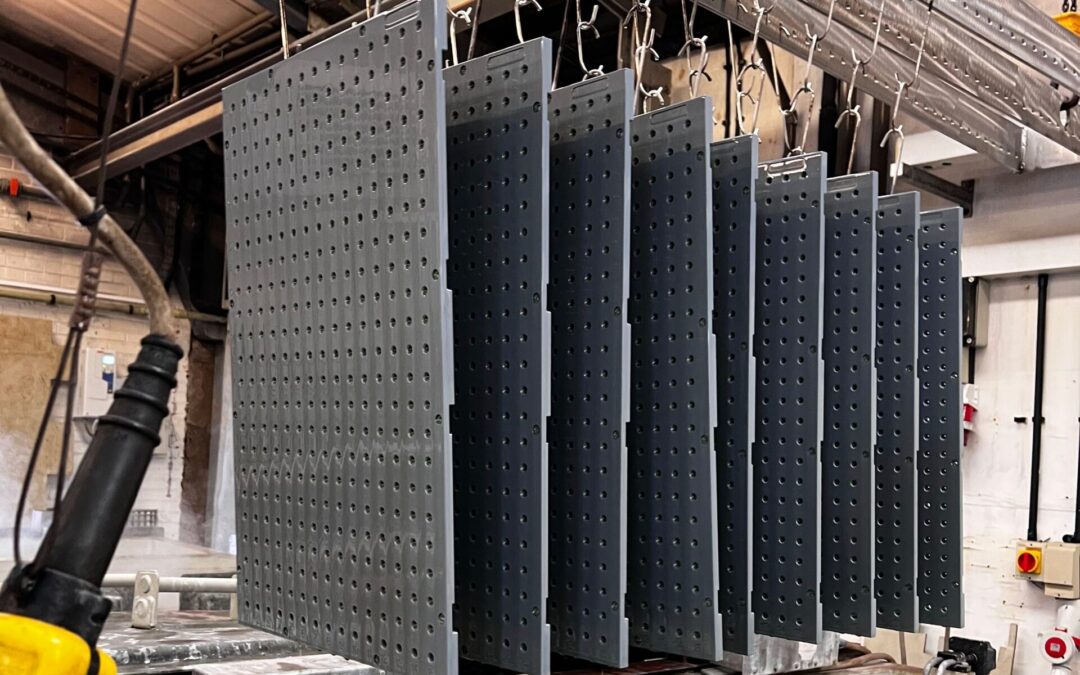

Why choose us for your anodising?

Hard Anodising services ensure immaculate results and fast turnaround times. No matter the complexity of your project, we have perfected our processes over the years. Therefore, allowing us to give our clients the very best results always. As a renowned anodising company in the UK, we continue to deliver a seamless service from start to finish, always abiding by the requirements of our clients. Whether it’s anodising large aluminium parts for your manufacturing business, or understanding whether hard anodising aluminium is right for your needs, we can help.

If you’d like more information on our Hard Anodising services, get in touch with our helpful team today. Call us at +44 (0)1562 67786 or via email at hdanodising@hotmail.com. We can walk you through our coating systems, offering you the ideal solution for your exact project. Or we can simply answer any questions you may have on the power of anodising.